I mainly deal with product design. My professional figure pushes me to be innovative and constantly evolving. I translate my curiosity into projects adapted to the industrial system. Being a product designer means following and controlling every phase of the creation of your product, from market analysis to the choice of the target, from design to the choice of suitable materials, from the engineering design to the development of the design up to marketing.

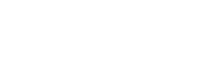

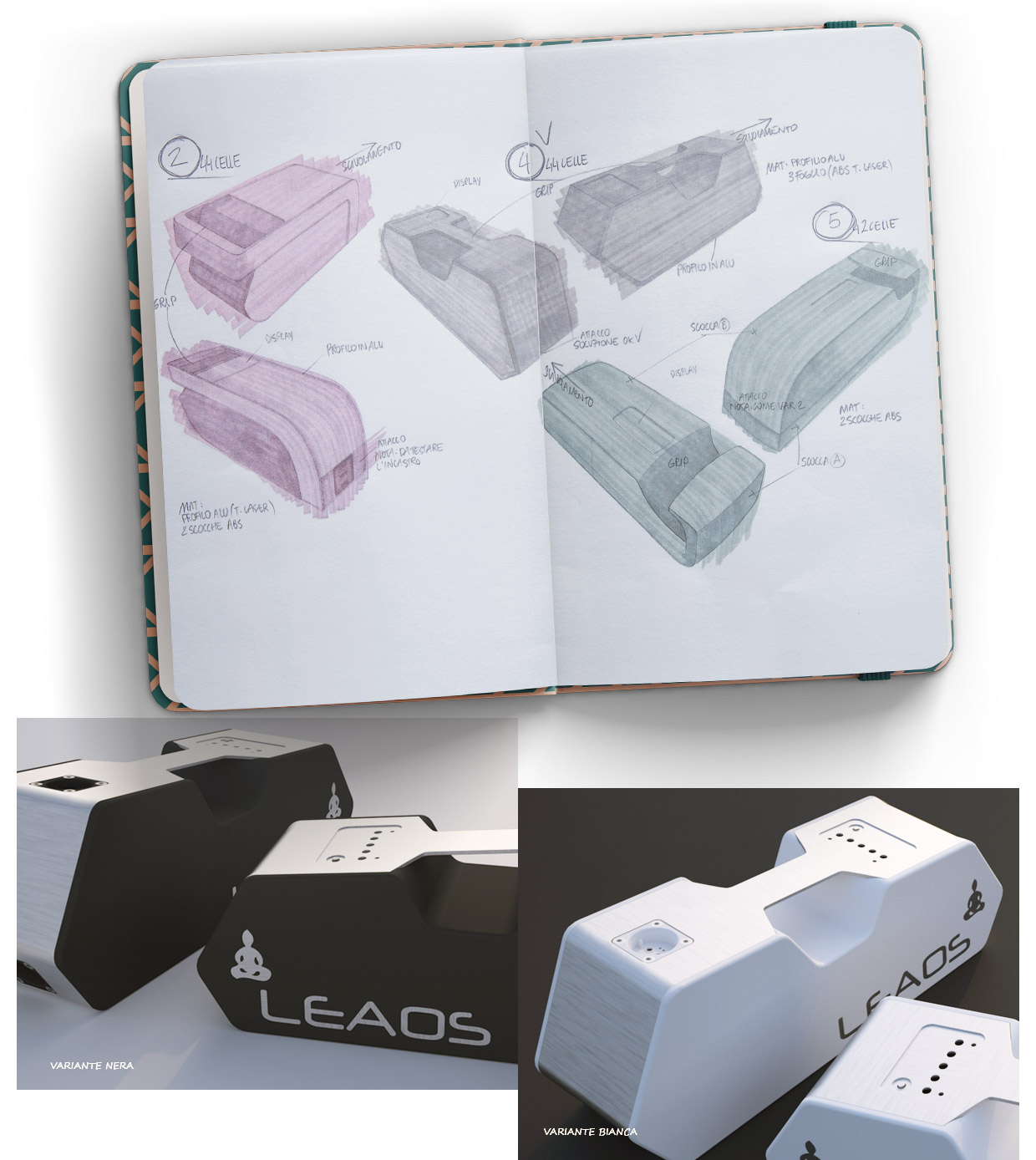

Client: LEAOS

Engineering design isn’t just about giving shape

The battery is tailor-made for the “Pure” electric bike. Pure (go to the project) is a completely innovative electric bike. In fact, it is a carbon fiber and Kevlar monocoque. For this reason, I strongly wanted to design an ad hoc battery. In addition, the battery is removable and waterproof; Designed and manufactured for high performance. The battery consists of an ABS shell. In other words, they are plastic sheets that are milled, folded and glued together. The volume contains 40 cells at 11.6Ah and consumption detectors. The battery is connected to a touch display. In short, it is possible to set the various speeds and keep an eye on mileage, consumption, (…)

How is the battery made?

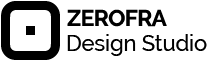

Engineering design requires 3 basic steps:

Market research and analysis. In this phase, the main characteristics of a product are defined in relation to the market and the type of object.

2D and 3D design. The idea is transformed into something tangible. The product is developed and refined through shape models, 3D prints and mathematical models.

Prototyping. Creating a prototype is the last step before production. Prototypes serve as a tool for controlling the design and its effectiveness.